In order to prevent castings from deformation, cracks and other defects due to rapid cooling after pouring, and to ensure that castings have sufficient strength and toughness during sand cleaning, castings should have sufficient cooling time in the mold. Continuously produced castings should be designed with sufficient cooling section length to ensure the cooling time of the castings.

The in-mold cooling time of castings is related to many factors such as the weight, wall thickness, complexity, alloy type, mold properties, production conditions and other factors of the castings.

一、Cooling time of cast iron parts in sand mold

The cooling time of cast iron parts in the sand mold is determined based on the temperature when unpacking. You can refer to the following data: 300-500°C for general castings; 200-300°C for castings prone to cold cracking and deformation; 200-300°C for castings prone to hot cracking Casting temperature is 800-900℃. Immediately after unpacking, remove the pouring riser and clean the sand core, then place it in a hot sand pit or enter the furnace to cool slowly.

1、The cooling time of cast iron parts in the sand mold can usually be selected by referring to Table 11-2-1 and Table 11-2-3.

Table 11-2-1 Cooling time of medium and small castings in the sand mold

|

Casting weight/kg |

<5 |

5~10 |

10~30 |

30~50 |

50~100 |

100~250 |

250~500 |

500~1000 |

|

Casting wall thickness/mm |

<8 |

<12 |

<18 |

<25 |

<30 |

<40 |

<50 |

<60 |

|

Cooling time/min |

20~30 |

25~40 |

30~60 |

50~100 |

80~160 |

120~300 |

240~600 |

480~720 |

Note: For castings with thin walls, light weight and simple structure, the cooling time should be taken as a small value, otherwise, the cooling time should be taken as a large value.

Table 11-2-2 Cooling time of large castings in sand mold

|

Casting weight/t |

1~5 |

5~10 |

10~15 |

15~20 |

20~30 |

30~50 |

50~70 |

70~100 |

|

Cooling time/h |

10~36 |

36~54 |

54~72 |

72~90 |

90~126 |

126~198 |

198~270 |

270~378 |

Note: When pit modeling, the casting cooling time needs to be increased by approximately 30%.

Table 11-2-3 Cooling time in the sand mold for medium and small castings during production pouring

|

weight/kg |

<5 |

5~10 |

10~30 |

30~50 |

50~100 |

100~250 |

250~500 |

|

Cooling time/min |

8~12 |

10~15 |

12~30 |

20~50 |

30~70 |

40~90 |

50~120 |

Note: 1. Casting weight refers to the total weight in each box

2、 Castings are forcedly cooled by ventilation on the production line, and the cooling time is short.

The in-mold cooling time of major iron castings can be calculated according to the following empirical formula.

t=vG (2-1)

in the formula t——Casting cooling time(h)

v——Casting cooling rate, take 4~8h/t

g——Casting weight (t)

k is the ratio of the weight of the casting to its contour volume. The larger the k value, the thicker the wall thickness of the casting and the longer the cooling time. The calculation formula of k is

k=G/V (2-2)

in the formula k——The weight of the casting and its contour volume ratio (t/m³);

G——Weight of casting (t)

V——Gradual outer contour volume(m³)

二、 Cooling time of steel castings in sand mold

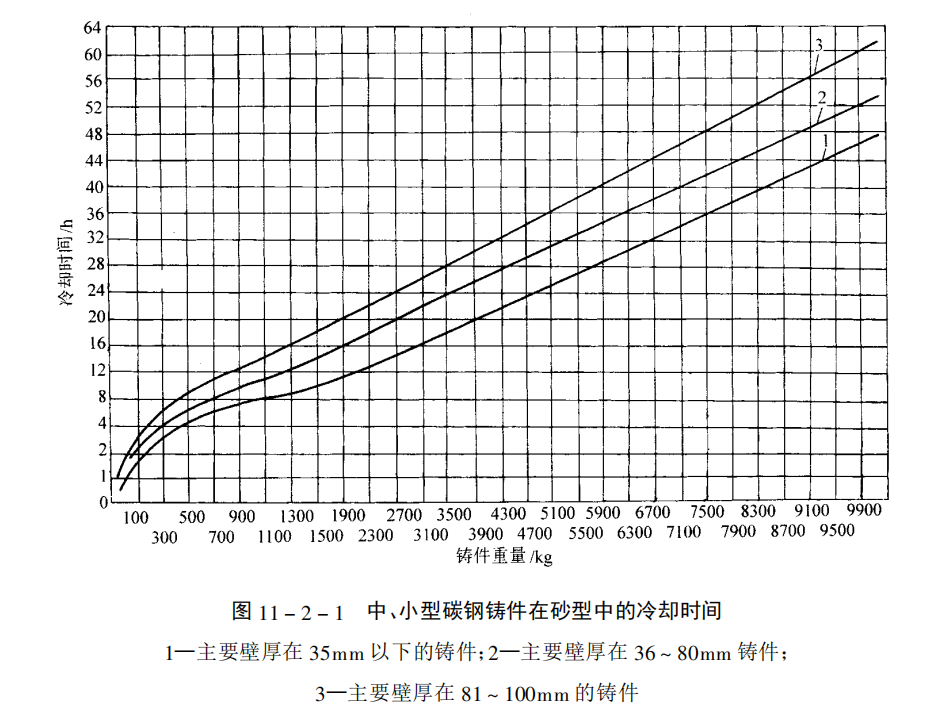

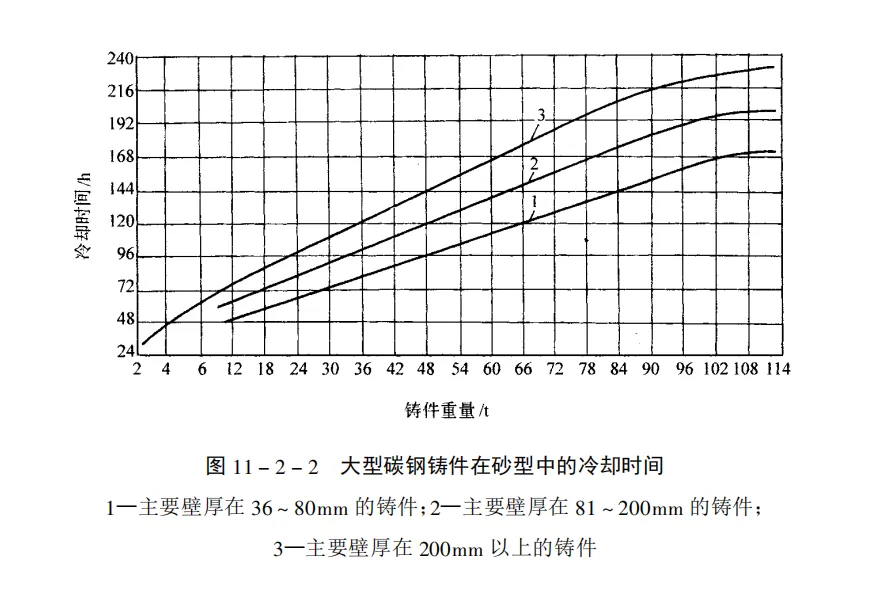

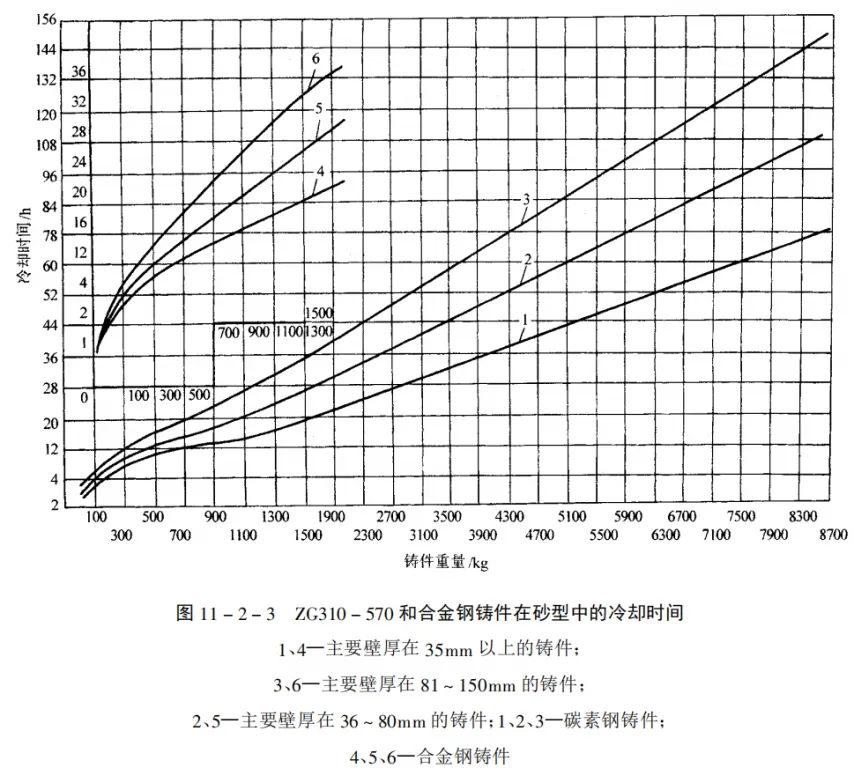

Steel castings for hydraulic sand cleaning, shot blasting sand cleaning and pneumatic tool sand cleaning should be cooled to 250-450°C in the sand mold to shake out. Falling sand above 450°C may cause deformation and cracks in castings. The cooling time in the sand mold can be seen in Figure 11-2-1 and Figure 11-2-3.

When using the above three pictures, you should pay attention to the following points:

(1) When the weight of carbon steel casting exceeds 110t, on the basis of finding the cooling time value corresponding to 110t according to Figure 11-2-2, for each additional 1t of weight, increase the cooling time by 1-3h.

(2) When the weight of ZG310-570 and alloy steel castings exceeds 8.5t, the cooling time can be doubled compared to the cooling time value of carbon steel castings obtained according to Figure 11-2-1 and Figure 11-2-2.

(3) Thick-walled castings (such as anvils, etc.) with simple shapes and uniform wall thickness can be loosened (or pried loose) 20-30% earlier than the cooling time specified in the figure. Such castings can also be naturally cooled in the pouring pit without heat treatment in the furnace, and the heat preservation time is calculated as 1.5-2t every 24 hours.

(4) For castings with complex structures, large wall thickness differences, and prone to cracks, the cooling time should be approximately 30% longer than the value specified in the figure.

(5) For some pit-shaped castings, the cover box needs to be lifted off in advance or the sand mold must be pried loose. This will increase the cooling rate, so the cooling time can be shortened by 10%.

三、Mold temperature of non-ferrous alloy castings

The molding temperature of non-ferrous alloy castings can be found according to Table 11-2-4.

Table 11-2-4 Extrusion temperature of non-ferrous alloy castings

|

Casting structural features |

Casting properties |

Alloy casting public welfare |

Casting site environment |

Casting exit temperature/℃ |

|

|

Small and medium items |

Large items |

||||

|

Simple shape and uniform wall thickness |

Coreless, wet core, wet type |

The tendency of hot cracking is small, such as AI-Si alloy |

The temperature is too high and there is no draft |

300~500 |

250~300 |

|

Dry core, dry type |

250~300 |

200~250 |

|||

|

Simple shape and uniform wall thickness |

Coreless, wet core, wet type |

The tendency of hot cracking is high, such as AI-Cu series alloys |

The temperature is low and there is draft |

250~300 |

200~250 |

|

Dry core, dry type |

200~250 |

150~200 |

|||

|

Complex shape and uneven wall thickness |

Coreless, wet core, wet type |

The tendency of hot cracking is small, such as AI-Si alloy |

The temperature is too high and there is no draft |

200~250 |

150~250 |

|

Dry core, dry type |

150~250 |

100~200 |

|||

|

Coreless, wet core, wet type |

The tendency of hot cracking is high, such as AI-Cu series alloys |

The temperature is low and there is draft |

150~200 |

100~200 |

|

|

Dry core, dry type |

100~150 |

<100 |

|||

Post time: May-26-2024