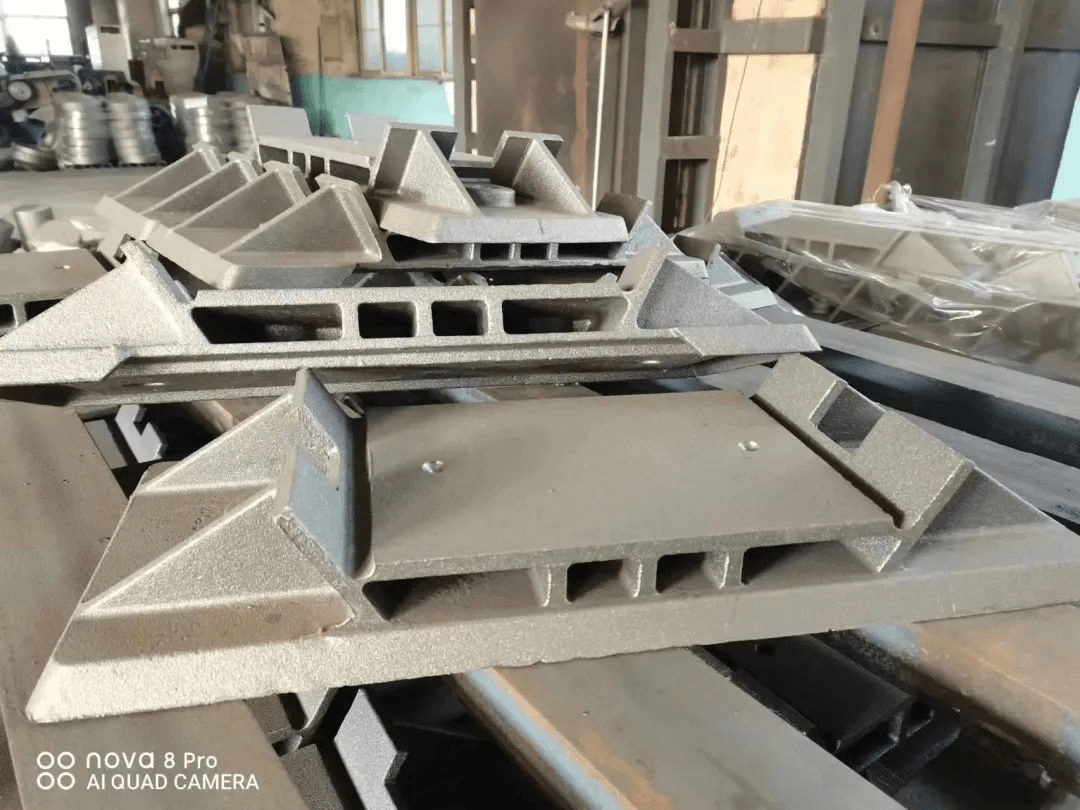

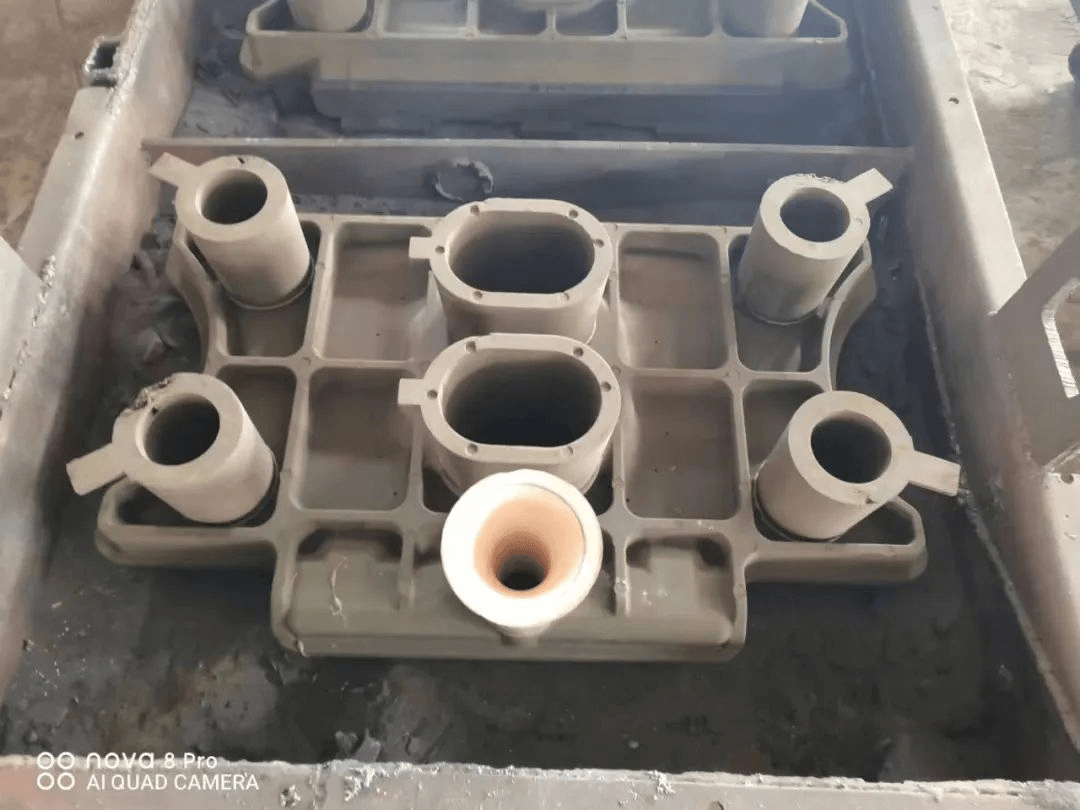

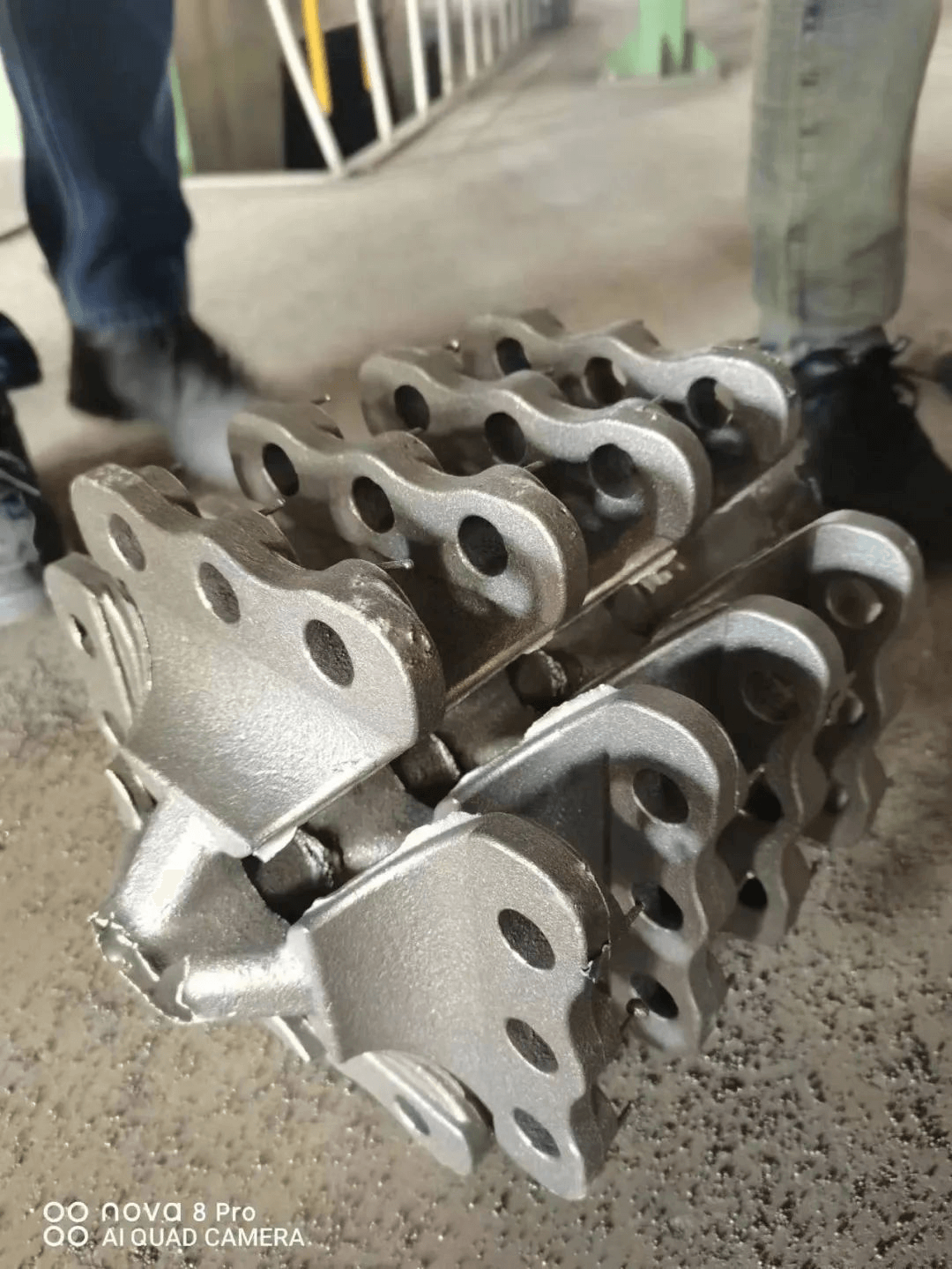

The application of ceramic sand shell precision casting process has developed rapidly in recent years, from the initial bucket teeth of construction machinery to the current general parts such as valves and plumbing, auto parts to tool hardware parts, from cast iron, cast carbon steel, to stainless steel, durable Hot steel and non-ferrous alloys have been extended to various fields of original sand casting, metal casting and precision casting, and have achieved good economic and social benefits.

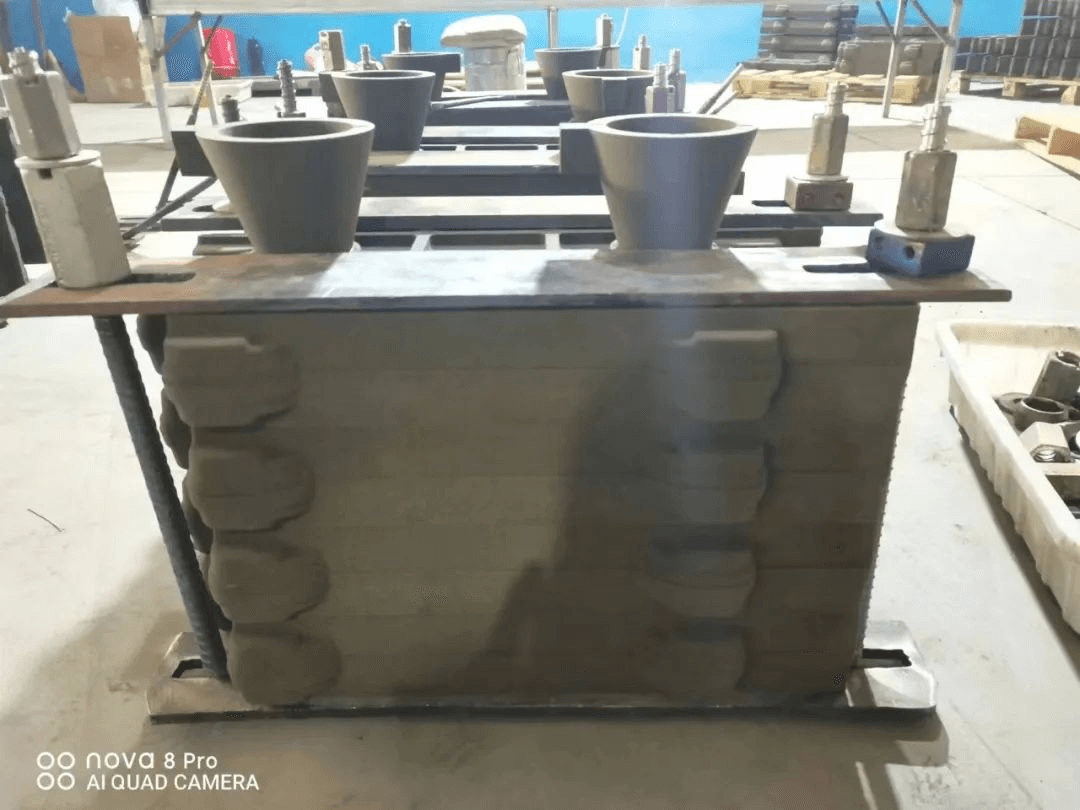

From the perspective of casting process, ceramic sand shell precision casting process has been widely used in the following three fields:

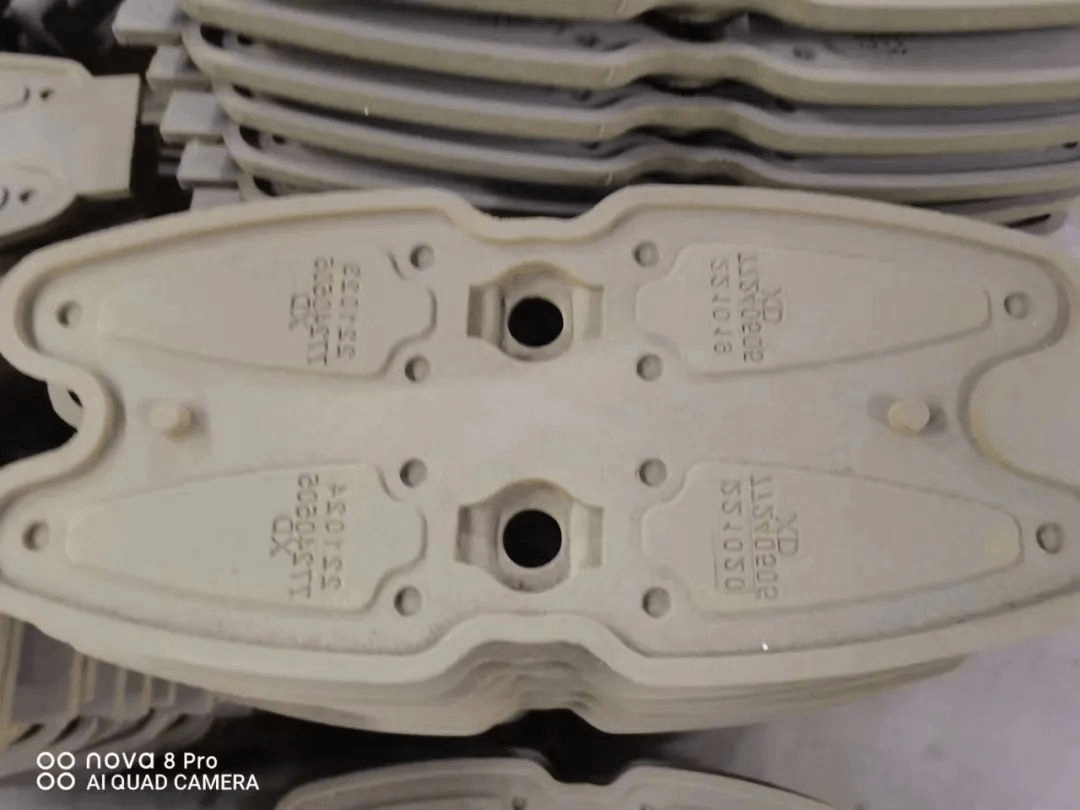

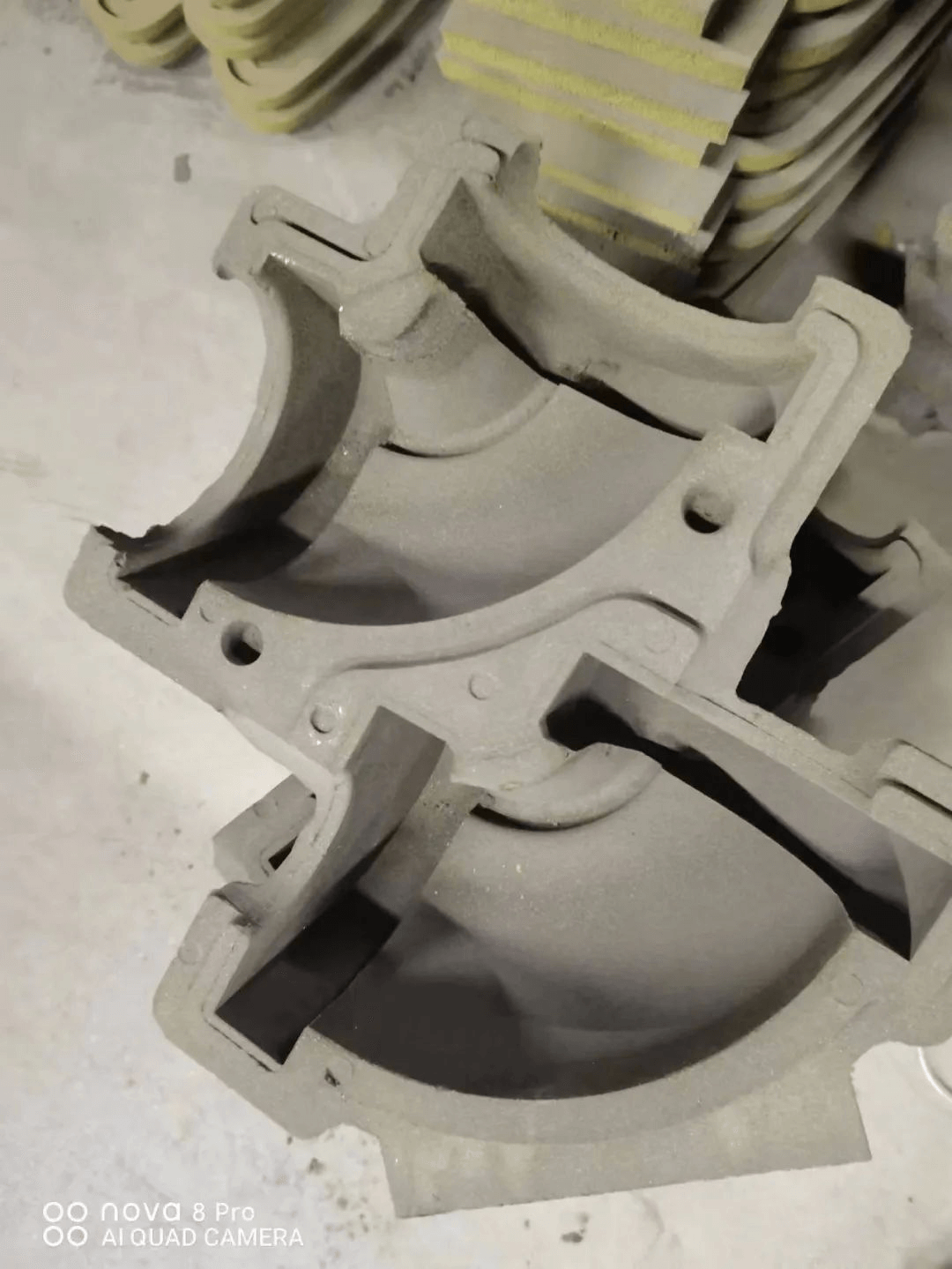

a. Partially replace the lost wax precision casting process. Especially some castings with relatively simple shapes and some castings that require cores, etc.;

b. Where the quartz sand shell casting was originally used, the ceramic sand shell precision casting process is used to improve the adaptability of the process;

c. The small steel castings originally produced by ordinary sand mold technology are replaced by new ceramic sand shell mold precision casting technology in order to improve the quality of castings, reduce the consumption of molding sand, and improve the production efficiency of castings.

In recent years, the development and application of ceramic sand coated sand has rapidly expanded the application range of shell mold casting process. Mainly due to:

1. The amount of resin added to the ceramic sand coated sand is small, the strength and toughness are high, the core sand has good fluidity and small gas generation;

2. Ceramic sand is neutral and has high refractoriness, suitable for casting of cast iron, cast steel (carbon steel, medium and low alloy steel, stainless steel, chrome steel, manganese steel) and non-ferrous alloys;

3. Ceramic sand particles have high hardness and strength, low crushing rate, high recycling rate, and less old sand discharge;

4. The thermal expansion of ceramic sand is small, which can significantly reduce the tendency of casting veins;

5. As artificial sand, ceramic sand has a wide particle size distribution, which is suitable for various casting processes and its' requirements. When fine sand is used, it still has high air permeability, which is conducive to improving the surface quality of castings.

Post time: May-05-2023