If the foundry sand is replaced by ceramic sand in the production of castings, many problems encountered in the production of furan resin self-setting sand process can be well solved.

Ceramic sand is artificial spherical sand with high refractoriness based on Al2O3. Generally, the alumina content is more than 60%, which is neutral sand. It basically does not react with furan resin and hardener, which can effectively reduce acid consumption and improve casting quality.

Compared with silica sand, the amount of resin and hardener addition to ceramic sand is significantly reduced. When the amount of resin added is reduced by 40%, the strength of molding sand is still higher than that of silica sand. While the casting cost is reduced, the gas output is reduced from sand molding or core, porosity defects are significantly reduced, the casting quality is improved, and the yield rate is increased.

For the reclamation of furan resin sand, at present, mechanical friction reclamation is mainly popular in China. Silica sand recycling adopts mechanical method. During the regeneration process, it will be broken, the overall particle size of the regeneration sand will become finer, the corresponding amount of resin added will further increase, and the venting performance of the molding sand will become worse. However the particle size of ceramic sand will almost no any change by mechanical friction method within 40 times, which can effectively ensure the quality of castings is stable.

In addition, silica sand is polygonal sand. In molding design, the draft angle of small and medium-sized pieces is generally designed at about 1%. Ceramic sand is spherical, and its relative friction is smaller than silica sand, so the draft angle can be reduced accordingly, saving the cost of subsequent machining. The reclaimation rate of silica sand is low, the general recovery rate is 90%~95%, more solid waste is generated, and there is much dust in the casting environment of the workshop. The reclaimation rate of ceramic sand can reach more than 98%, which can effectively reduce solid waste discharge and make the production workshop more green and healthy.

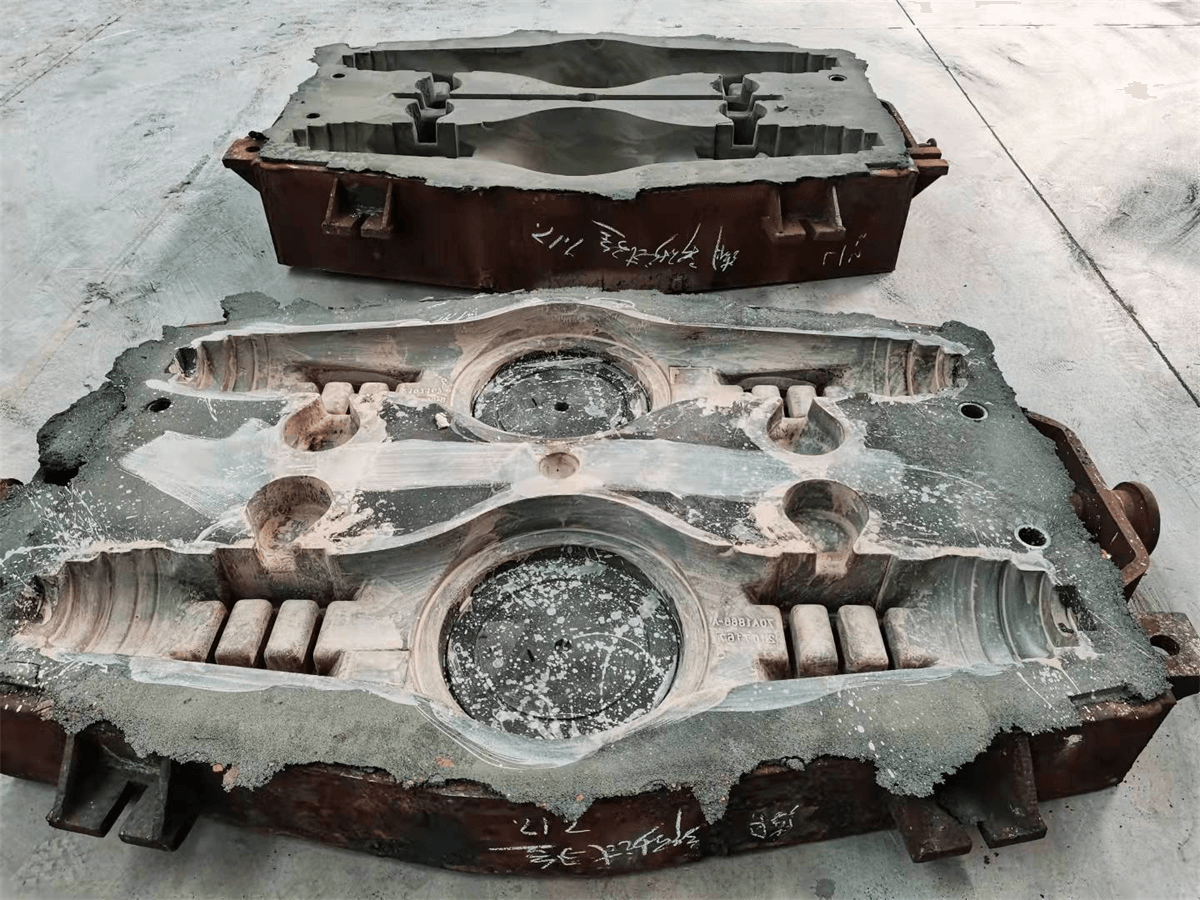

Ceramic sand has high refractoriness, close to spherical grain shape and good fluidity. During the production process of castings, basically no sticky sand defects will occur, which can effectively reduce the workload of cleaning and grinding. Moreover, the grade or amount of coating can be reduced, further reducing the production cost of castings.

Post time: Jun-14-2023