Although the price of ceramic sand is much higher than that of silica sand and quartz sand, if it is used properly and calculated comprehensively, it can not only significantly improve the quality of castings, but also reduce production costs.

1. The refractoriness of ceramic sand is higher than that of silica sand, and the compactness of filling during molding is high, so the surface quality of castings can be improved and the scrap rate in production can be reduced;

2. Spherical ceramic sand has good fluidity. For complex-shaped castings, it is easy to fill tight parts that are difficult to fill, such as inner angles, deep recesses, and flat holes. Therefore, it can significantly reduce the sand-packing defects in these parts, and greatly reduce the workload of cleaning and finishing;

3. Good crush resistance, high recovery rate, and correspondingly reduced waste emissions;

4. The thermal expansion rate is small, the thermal stability is good, and the secondary phase transition will not cause expansion defects, which greatly improves the dimensional accuracy

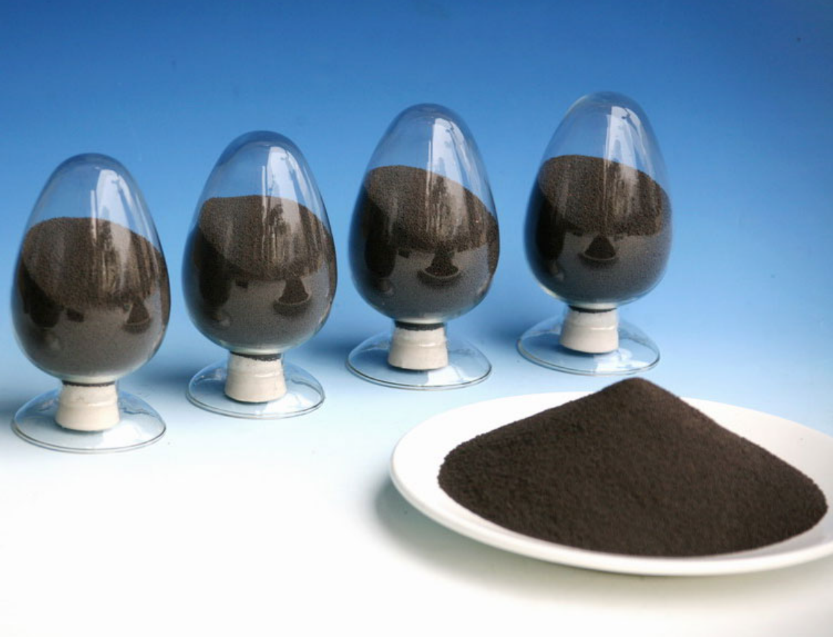

The surface of the ceramic sand is very smooth, and the adhesive film on the surface of the sand grains can be peeled off with a slight friction of the old sand. The ceramic sand particles have high hardness and are not easy to break, so the reclamation ability of the ceramic sand is particularly strong. Moreover, both thermal reclamation and mechanical reclamation methods are suitable for ceramic sand. Relatively speaking, after the foundry uses ceramic sand, it can collect the old sand without too much cost. It only needs to remove the bonded part of the sand surface, and then it can be regenerated and reused after screening. In this way, the ceramic sand can be recycled and repeated use. Depending on the quality level of the reclamation equipment, the ceramic sand reclamation times are generally 50-100 times, and some customers even reach 200 times, which greatly reduces the cost of use, which cannot be replaced by other foundry sands.

The casting produce by ceramic sand which have reclaimed more than 20 times.

It can be said that the use of ceramic sand, reclamation is a great tool, which is unmatched by other foundry sand

Post time: Aug-08-2023